Dairy companies are committed to providing their employees with a safe working environment. Companies are constantly working to improve their employees’ safety on a day-to-day basis. Strong workforce management that promotes a culture of safety and fosters employee productivity and engagement is vital to profitability and long-term business success. To do this, dairy companies conduct workplace safety trainings and create safety committees and teams, which are instrumental to maintaining a safety-conscious culture in the plant.

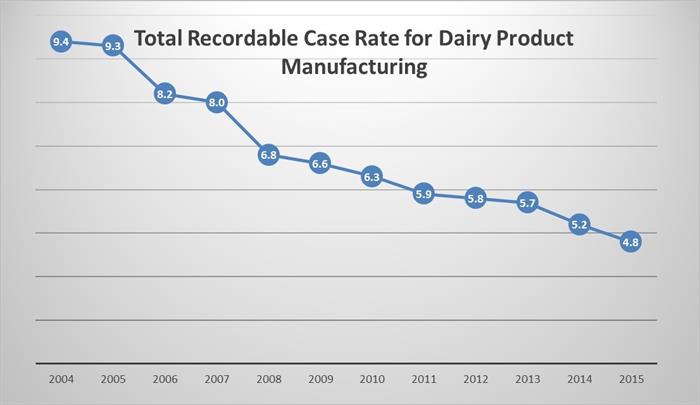

Statistics gathered by the Bureau of Labor Statistics demonstrate the dairy industry’s commitment to continuously improving safety in dairy facilities. As seen in figure one, the dairy industry has consistently decreased its total recordable case (TRC)rates of occupational injuries or illness*over the past 10 years. The dairy product manufacturing as a whole has nearly halved its TRC rate, falling from 9.4 injuries and illnesses per 100 full-time workers in 2004 to 4.8 injuries and illnesses per 100 full-time workers in 2015.

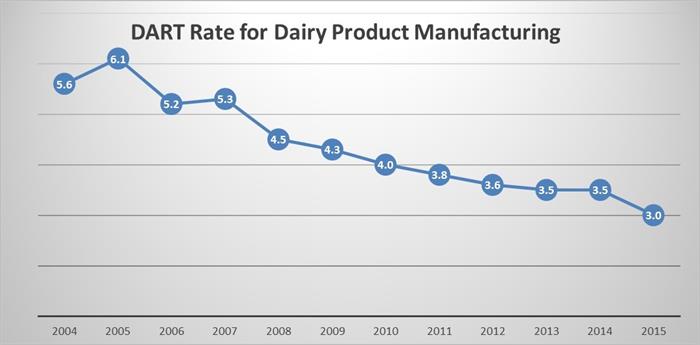

The same story can be seen in the industry’s days away from work, restrictions and transfers (DART) rate* (see figure two), which reflects the number of days that workers are unable to perform their core job function because of an accident or illness. These rates continue to improve as the result of employee engagement and a strong safety culture within the dairy industry.

However, the dairy industry is not done improving its safety standards. Every year IDFA recognizes the dairy companies and distribution facilities that go the extra mile in ensuring the safety of their workers. For 13 years, the awards have recognized companies and facilities with the lowest DART rates in their respective commodity type, with many of them at or near zero lost days. The current criteria recognize winning plants or trucking operations that implement effective and innovative health and safety programs and have illness and injury rates below the industry average. These plants are at the forefront of initiating best practices such as implementing employee-led safety committees, job observations and coaching, workplace condition monitoring and hazard analysis.

Overall, makers of milk, cheese, dry dairy products, and ice cream have and remain committed to making their facilities safer for their employees while supplying high quality products to consumers.

IDFA members can log-in at the top of the page to see more detailed workplace safety statistics about the dairy industry.

* Total recordable case rate is calculated by total recordable cases multiplied by 200,000 and dividing that by total number of hours worked. DART rate is calculated by total days away from work, restrictions or transfer multiplied by 200,000 and dividing that by total number of hours worked.

IDFA Members can see more detailed analysis and information if they login in at the top of the page.

For information about IDFA membership, contact us at membership@idfa.org.